Lower-lash setting has long been a common pain point for beauty users: traditional brush heads either lose hold after setting, or are too large, causing product to smear onto the skin and making it difficult to reach the lash roots precisely. To address this, we introduce a new aluminum mascara tube paired with a stainless steel threaded brush head. Through material upgrades and structural optimization, this design solves lower-lash setting challenges from a real user-experience perspective.

Pain Point Insights: Why Traditional Mascara Brushes Fall Short

1. Insufficient long-lasting hold for lower lashes

Most conventional brush heads use plastic or nylon. After application, lower lashes can collapse under gravity or frequent blinking. Many users report: “They look lifted right after brushing, but after 30 minutes the lower lashes fall flat.”

2. Conflict between brush size and application precision

Standard brush diameters are typically 5–8 mm. The lower-lash area is narrow, making it difficult for the brush to reach the roots precisely. It also easily touches the eyelid skin, requiring repeated clean-up and reducing makeup efficiency.

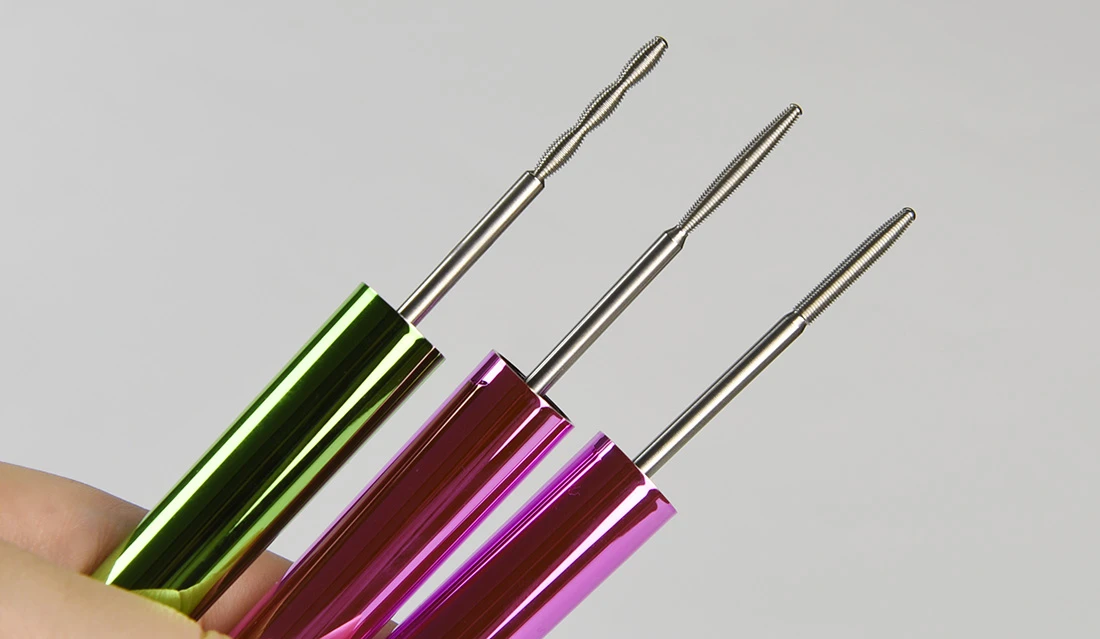

Technical Upgrades: Dual Design of a Stainless Steel Threaded Brush + Aluminum Tube Body

(1) Aluminum Mascara Tube: Better Grip and Compatibility with Precision Brush Heads

The tube body is made with a plastic inner tube and an aluminum outer sleeve. Wall thickness is controlled at 0.8–1.2 mm, enhancing grip and a premium feel for more stable handling. The surface is anodized for corrosion resistance and reduced fingerprint marks, helping the tube stay deformation-free during long-term use.

(2) Stainless Steel Threaded Brush Head: Three Design Improvements That Solve the Core Issues

1. Ultra-slim brush diameter tailored for the lower-lash area

The brush diameter is controlled at 2.5–3.5 mm (about 1/2 to 1/3 of traditional brushes). The slim stem reaches deep to the lash roots, and the brush tip is only 0.5 mm—making it easy to comb fine corner lashes while reducing skin-smearing issues.

2. Threaded groove structure for even lash separation

The brush surface uses a spiral groove design. When lashes enter the grooves, they naturally separate to avoid clumping. At the same time, the grooves carry a controlled amount of mascara, helping each lash coat evenly and reducing the risk of heavy deposits.

3. 316L stainless steel for stronger support and longer setting

The brush body is made of 316L stainless steel, with hardness up to HV200 and an elastic modulus of 200 GPa. Compared with plastic brush heads, support strength increases by 2–3×. During application, it “lifts” the lashes and holds the curve, achieving a setting effect lasting over 8 hours.

Market Fit: From User Needs to Custom Production Capability

To meet different brand requirements for brush details and tube finishing, we leverage integrated injection molding and aluminum shell production capabilities to offer two cooperation models:

Stock molds for fast response: We have three standard slim brush heads (diameter 2.5 mm / 3.0 mm / 3.5 mm) with existing plastic tube molds and aluminum shells, allowing sample lead time to be shortened to 7 days.

Custom tooling service: Customization is available for brush diameter, thread density (1–3 threads/mm), and tube color (6 anodized color options). Tooling development lead time is 25–30 days to support brand-specific design needs.

In mold manufacturing, the Sambound Packaging team uses high-precision CNC machining to control the threaded groove tolerance to approximately ±0.05 mm, preventing uneven lash separation caused by structural deviation.

Conclusion

This new combination of an aluminum mascara tube and a stainless steel threaded brush head delivers a practical improvement for lower-lash application through three layers of design: “slim brush + threaded separation + stainless steel support.” It addresses common issues such as lashes collapsing after setting and imprecise application. With flexible stock-mold options and custom production capability, it fits beauty brands targeting specialized lower-lash use scenarios.