For a mascara to truly perform well, two factors are essential: the formula (bulk) and the brush head design. The formula determines adhesion, film-forming speed, and wear longevity, while the brush head affects pickup volume, combing evenness, clumping tendency, and application precision. When the SamBound cosmetic packaging team reviewed mainstream brush-head solutions, we found the market largely falls into three categories: fiber spiral brushes, silicone brushes, and zinc-alloy brushes. These differ significantly in their process routes, cost structures, and user experiences. This article organizes the key points—from structural principles and production processes to cost and makeup performance—so you can match brush design to product positioning and target consumers faster.

What Is a Fiber Spiral Mascara Brush Head?

A fiber spiral brush head is mainly composed of a metal wire core and nylon fibers. During production, nylon fibers are arranged to a specified length, then twisted and clamped into place by spiral-winding metal wire. This creates a stable spiral distribution of bristles. In use, it helps comb lashes and apply mascara evenly, reducing clumping and product buildup.

Fiber Spiral Mascara Brush Head Manufacturing Process

- Metal wire parameter setup: Define wire diameter, hardness, and winding tension based on product specifications; prepare for spiral forming.

- Fiber feeding: Nylon or other fibers are continuously fed into fully automated equipment at the preset length.

- Spiral bristle clamping/forming: Metal wire is spiral-wound to clamp fibers, forming a uniform, continuous spiral brush body.

- Automatic setting: Stabilize the spiral structure and bristle angles to ensure brush-head consistency.

- Cutting/finishing: The machine cuts to the specified size, outputting individual brush heads.

![]()

What Is a Silicone Mascara Brush Head?

A silicone mascara brush head is an integrated applicator with fine “bristle” features, made from 40–50 Shore A food-grade silicone. It is formed through a high-precision mold using injection molding and/or compression molding with vulcanization (curing).

Silicone Mascara Brush Head Manufacturing Process

- Mold preparation: Design cavity count based on brush-head size; CNC-machine the production mold for mass manufacturing.

- Silicone compounding: Select food-grade silicone (40–50 Shore A), mix additives, and blend uniformly.

- Molding: Standard silicone uses compression molding with vulcanization; liquid silicone rubber (LSR) uses injection molding. Both require precise control of temperature, pressure, and process parameters.

- Post-processing/trim: Demold parts and remove flash to obtain individual silicone brush heads.

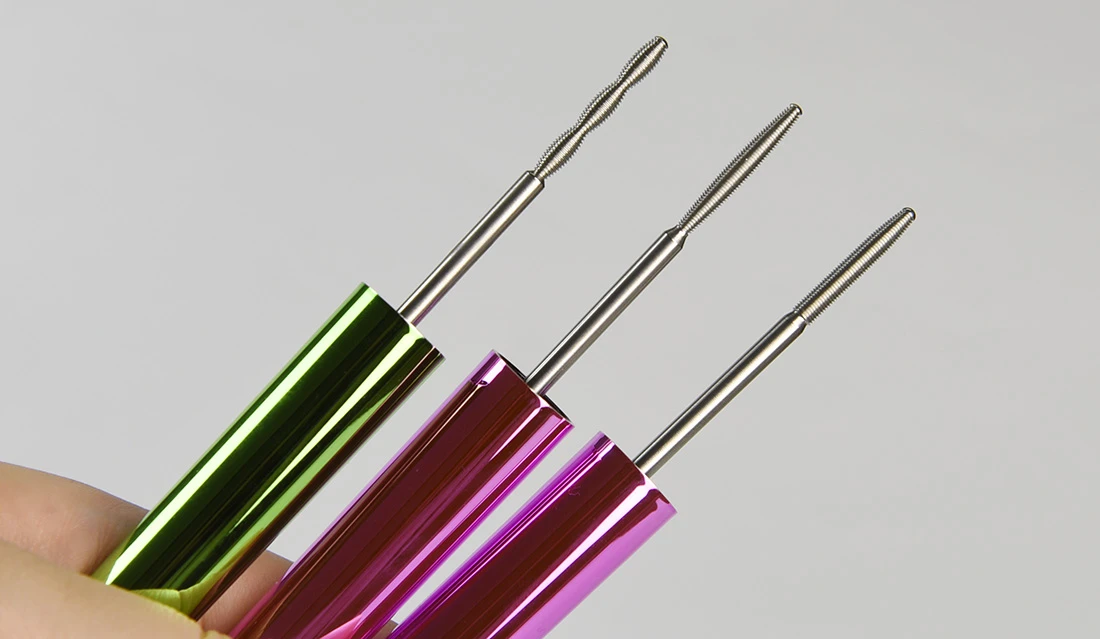

What Is a Zinc-Alloy Mascara Brush Head?

A zinc-alloy mascara brush head is a metallic-texture brush made from an eco-friendly, low-lead zinc alloy. It typically features a dense spiral-tooth structure with a uniform tooth pattern and metallic luster (a classic appearance from die casting + electroplating). The rod is smooth metal. Its tooth geometry can be made with high precision, making it durable and resistant to deformation while providing even mascara pickup—balancing premium feel and practical performance.

Zinc-Alloy Mascara Brush Head Manufacturing Process

- Mold preparation: Machine high-precision cavities; optimize runner and venting design; prepare for die casting.

- Zinc-alloy melting: Use eco-friendly low-lead zinc alloy; melt, degas, filter; control temperature at 420–440°C.

- Die casting: Form parts on a die-casting machine; precisely control mold temperature (180–220°C) and injection parameters.

- Post-processing/finishing: Trim gates/flash and deburr. For complex shapes or fine-tooth designs, add precision 5-axis CNC machining.

- Surface finishing: After polishing and cleaning, apply cyanide-free electroplating (nickel/chrome layers) to improve corrosion resistance and aesthetics—resulting in a finished zinc-alloy brush head.

Cost Comparison Table of Three Mascara Brush Types

Cost Breakdown (Core Cost Components & Typical Share)

| Comparison Dimension | Zinc-Alloy Brush Head | Silicone Brush Head | Fiber Spiral Brush Head |

|---|---|---|---|

| Core cost components & share | 1) Raw material (zinc alloy) 35–45% 2) Processing (die casting/trim/CNC) 20–30% 3) Surface finishing (electroplating) 10–20% 4) Tooling 5–15% 5) Hidden costs 3–8% 6) Other costs 5–10% | 1) Raw material (silicone) 40–50% 2) Tooling 15–20% 3) Processing (injection/curing/trim) 20–25% 4) Hidden costs 3–8% 5) Other costs 5–10% | 1) Raw material (metal wire + PBT/nylon fibers) 45–55% 2) Processing (fiber clamping/spiral winding/trimming) 35–45% 3) Hidden costs (scrap rate 3–5%) 3–8% 4) Other costs 2–5% |

Unit Cost Reference (100,000 pcs batch)

| Type | Unit Cost (USD/pc) |

|---|---|

| Zinc-alloy brush head | 1) $0.21–$0.36/pc (standard electroplating) 2) $0.40–$0.50/pc (vacuum metallization) |

| Silicone brush head | 1) $0.09–$0.17/pc (standard silicone) 2) $0.14–$0.26/pc (food-grade silicone) |

| Fiber spiral brush head | 1) $0.04–$0.09/pc (standard fiber density) 2) $0.07–$0.13/pc (high-density fiber) |

Key Fixed Cost Items

| Type | Key Fixed Cost Item |

|---|---|

| Zinc-alloy brush head | Die-casting mold cost (one-time: $714–$2,857) |

| Silicone brush head | Silicone injection mold cost (one-time: $714–$1,429) |

| Fiber spiral brush head | No mold cost; only high-precision versions require spiral positioning fixtures (one-time: $286–$714, reusable) |

Main Cost-Optimization Opportunities

| Type | Main Optimization Space |

|---|---|

| Zinc-alloy brush head | 1) Solid-to-hollow design (reduce material cost by ~23%) 2) Partial plating instead of full plating (save ~40% surface-finishing cost) 3) Recycle and discount scrap material |

| Silicone brush head | 1) Medical-grade instead of food-grade (reduce material cost by ~8%) 2) China-made silicone instead of imported (reduce by ~10–15%) 3) Automated production lines reduce labor (~30%) |

| Fiber spiral brush head | 1) China-made fiber instead of imported (reduce material cost by ~15%) 2) Improve fiber utilization (target ≥95%) 3) Automated winding equipment reduces labor (~25%) |

Typical Applications

| Type | Recommended Positioning / Use Scenarios |

|---|---|

| Zinc-alloy brush head | Premium positioning, metallic feel requirement, high durability for reusable designs |

| Silicone brush head | Mid-to-premium positioning, skin-friendly/no shedding, customized special shapes for reusable designs |

| Fiber spiral brush head | Mass-market positioning, disposable-use scenarios, value-for-money priority, large-volume baseline products |

Evolution Timeline of Mascara Brush Heads: When Three Core Materials Emerged

Spiral Brush (Fiber Spiral)

Originating in the late 1990s, its core concept is using a spiral-wound metal wire to secure bristles. This structure wraps lashes evenly and helps create fuller, longer-looking results. After broad promotion by major brands in the early 2000s, it became the industry standard and remains mainstream today.

Zinc-Alloy Brush

It rose in popularity after the 2000s. The material’s rigidity can effectively support lashes from the root and help maintain a longer-lasting curl. Many patents focus on distinctive shape designs, with varied forms, becoming a marker of more “professional” makeup effects.

Silicone Brush

It began to disrupt traditional designs in the mid-2000s. Elastic silicone can precisely grip and distribute mascara more evenly, addressing heavy buildup and clumping at the source. It enables a cleaner, more separated lash look and helps trigger a trend toward “ultra-clean” finish styles.

Pros & Cons Comparison: User Experience of Three Mascara Brush Types

| Comparison Dimension | Silicone Brush Head | Fiber Spiral Brush Head | Zinc-Alloy Brush Head |

|---|---|---|---|

| Makeup performance | Pros: Well-separated lashes, natural length and density, not heavy-looking. Cons: Some versions may clump and form “spider legs”; uneven application. | Pros: Fibers and formula adhere evenly with an airy look; can be layered to adjust results. Cons: Low-quality versions look patchy/clumpy; budget versions perform poorly. | Pros: Even pickup without clumping; long-lasting setting; water/sweat resistance; strong curl hold. Cons: Some pick up less product and look weaker; heat conduction may dry the formula, causing clumping/smudging. |

| Ease of use | Pros: Beginner-friendly; soft and less likely to poke; precise for lower lashes. Cons: Too hard may poke; too soft may deform; Z-shaped technique can be hard; thick heads struggle at inner/outer corners. | Pros: Beginner/lazy-user friendly; convenient operation; fits eye shape well; good for lower lashes. Cons: Some are hard to control and may smudge lids; fast-drying requires quick application. | Pros: Firm, stable, and easier to control force; precise on small lashes; beginner-friendly. Cons: Often heavier and causes wrist fatigue; can slip; beginners need time to adapt to the weight to avoid poking. |

| Suitable users / skin & eye sensitivity | Pros: Some are friendly for sensitive eyes. Cons: Hooded/single eyelids may smudge more easily; sensitive skin may have allergic reactions. | Pros: Works for oily eyelids; student-friendly. Cons: Not ideal for sensitive eyes; low-quality versions may irritate the eye area. | Pros: Sensitive-eye friendly (high-quality versions); suitable for people pursuing refined lash definition. Cons: No major skin-type limitation; beginners need to adapt to the weight. |

| Hygiene & cleaning | Pros: Smooth surface, easy to clean, less residue, fewer bacteria. Cons: Low-quality versions may retain residue, breed bacteria and odor, and shed flakes. | Pros: High-quality versions remove easily with minimal residue. Cons: Low-quality fibers may remain; repeated cleaning is needed. | Pros: High-quality versions are easy to rinse clean; less likely to breed bacteria. Cons: Gaps between teeth can trap mascara, making cleaning difficult. |

| Durability | Pros: No particularly standout advantage. Cons: Some may deform easily. | Pros: No particularly standout advantage. Cons: Low-quality fibers may shed or break. | Pros: Metal is less likely to deform; more durable than plastic/silicone. Cons: If edges have burrs, they may cause wear/abrasion. |

| Cost-performance | Pros: Affordable options available; student-friendly. Cons: Some versions offer low value for money. | Pros: Many budget options; generally high cost-performance; student-friendly. Cons: Very low-priced versions have poor quality and discounted results. | Pros: High-quality versions can be cost-effective over long-term use. Cons: Some are more “flashy than functional,” with higher prices. |

| Core limitations | Some do not fit Asian eye shapes well; pickup amount is hard to control; may introduce air bubbles. | Fiber quality varies; shedding can irritate eyes; design defects in grooves can lead to uneven formula distribution. | Excess weight can cause wrist fatigue; feels cold in winter; too rigid with poor flexibility and fit. |

Conclusion

There is no absolute “best” mascara brush head—what matters is positioning and target users. If you want mass volume, strong value, and a mainstream lash effect, prioritize a fiber spiral brush. If you want a clean, separated finish, easier cleaning, sensitivity-friendly (in some versions), and differentiated shapes, choose a silicone brush. If you want a premium metallic feel, strong curl-setting, and high durability, choose a zinc-alloy brush. Define your target users, key lash-effect selling points, and price band first, and the right brush-head solution will naturally align.