After cosmetic packaging products are formed by injection molding, they usually require surface decoration. Companies often add graphics and text to promote products and brand identity. There are many surface decoration processes, such as screen printing, pad printing, heat transfer, hot stamping, and water transfer. Today, we will introduce the principle of screen printing and the key precautions of this process.

1. What is Screen Printing?

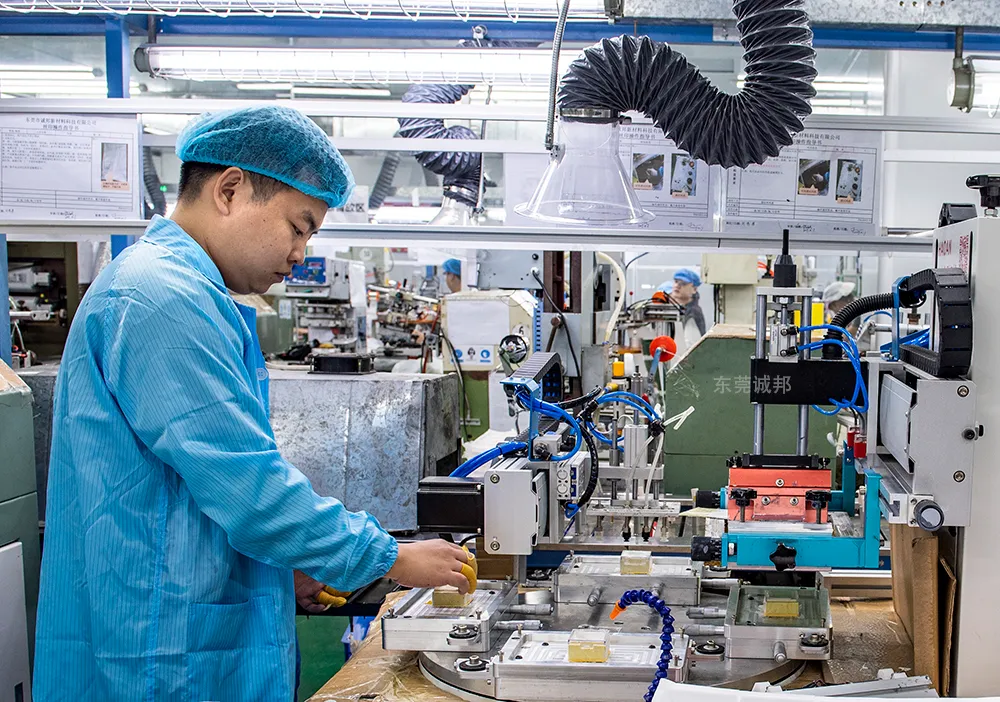

The basic principle of screen printing is: the mesh openings in the graphic area of the screen plate allow ink to pass through, while the non-graphic areas do not. In simple terms, the desired pattern is prepared in advance on the screen plate. During printing, ink is poured at one end of the screen plate, and the squeegee applies pressure while moving across the plate. The ink is pressed through the mesh openings of the graphic area and transferred onto the substrate.

Due to the adhesion of the ink, the print remains fixed within a defined area. During the process, the squeegee is always in line contact with both the screen and the substrate. This moving line contact ensures precision and prevents smudging. After the squeegee finishes, the screen rebounds, separating from the substrate and ensuring clean edges and dimensional accuracy. Once lifted, the ink is returned to the starting position, completing one printing cycle.

2. Precautions in Screen Printing

- Screen printing is usually used for text and graphics on packaging products. It has a strong influence on product image, so higher technical standards are required.

- Glass bottles: When printing on transparent, frosted, or spray-coated bottles, high-temperature ink should be used. The color is baked at high temperature, making it resistant to fading and scratches, though the color is typically matte. Work with suppliers who have high-temperature furnaces.

- Design considerations: Limit the number of colors, use negative films, and avoid fonts, patterns, or lines that are too thin or too large. Otherwise, issues like ink buildup or broken lines may occur. Always confirm with samples before mass production to avoid color differences.

- If misprints occur on frosted glass bottles, they can be re-polished and reprinted, though additional processing fees will apply.

- Round bottles with one color are counted as one color print. Flat or oval bottles are calculated based on the number of print areas and print colors.

- Plastic containers: Inks are divided into normal and UV inks. UV inks are widely used, offering a glossy and three-dimensional look, resistant to fading, and capable of multicolor printing. The minimum order quantity is usually 1,000 pieces.

- Both glass and plastic bottle printing require plate-making fees. If the factory does not have a matching jig for a new specification, an additional jig fee will be charged. However, these costs may be offset once order volume reaches a certain level.

- Before mass printing, proof samples must be made to confirm the quality. Once approved, production usually takes 4–5 days, depending on complexity and quantity.

- Most screen printing factories also offer hot stamping (gold/silver foil), manual or mechanical printing, pad printing, and self-adhesive label printing.

- When using screen-printed bottles, avoid excessive handling or collisions to prevent scratches. Select proper sterilization methods to protect printed surfaces.

- Screen printing always incurs costs, and poor results may cause entire batches to be scrapped. Spot color percentage mesh printing can achieve richer colors, but testing is essential.